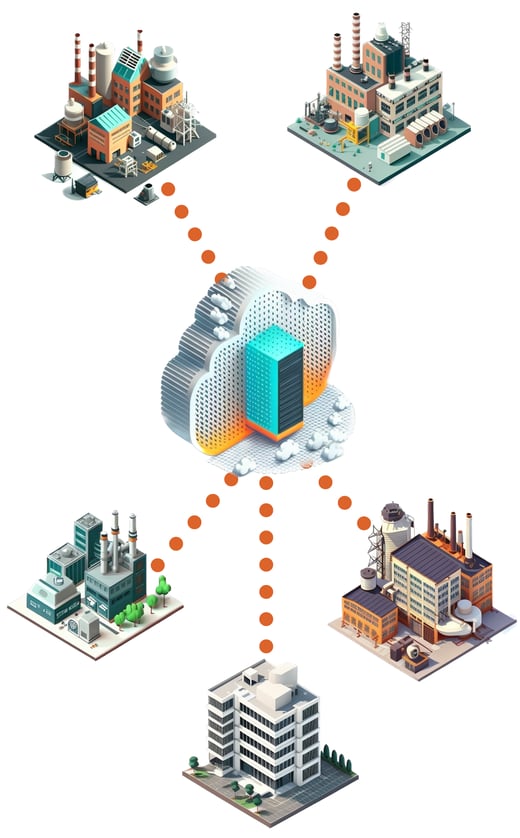

Metcal CV-IOT Gateway

15:05 - 30/05/2023

HIGH QUALITY PRODUCTS IN THE WELDING AND CUTTING TECHNOLOGY INDUSTRY IMPRESSED AT METAL & WELD 2023 (NICHIA / NIKKO-Japan welding materials)

Opening of Vietnam Industry and Manufacturing Exhibition (VIMF) 2023

The North has its first semiconductor production project

VinFast officially listed on Nasdaq Globalmarket, capitalization of more than 23 billion USD

|

ROBOTICS

ROBOTICS  SEMICONDUCTOR (MSW KOREA)

SEMICONDUCTOR (MSW KOREA)  CRYSTAL SENSOR (QCM)

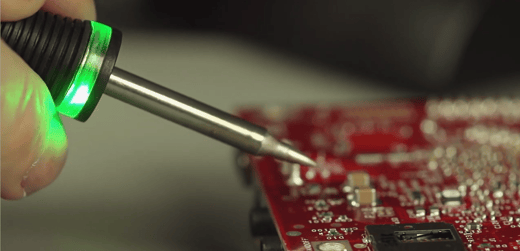

CRYSTAL SENSOR (QCM)  LEAD SOLDERING

LEAD SOLDERING  SOLDERING MACHINE (METCAL)

SOLDERING MACHINE (METCAL)  SPOT WELDING (UNION)

SPOT WELDING (UNION)  IONIZER BLOWER (CORE INSIGHT)

IONIZER BLOWER (CORE INSIGHT)  SPRING BALANCER (TIGON)

SPRING BALANCER (TIGON)  TIG+LASER WELDING (NICHIA)

TIG+LASER WELDING (NICHIA)